Supply chains have come under increasing pressure during the last couple of years. Not just the covid-19 pandemic, but rising costs, material shortages, and geopolitical and ecological changes have disrupted supply chains all across the world. Furthermore, changing market forces, such as security regulations, industry mandates, and shifting customer demands, pressure supply chains to be more adaptable, agile and resilient.

Among the most affected industries by the havoc caused by supply chain disruptions, is the life sciences industry. As covid-19 caused the world to come to a standstill, supply chains were disrupted and broken due to limitations on import/export, travel, and personnel shortages. Furthermore, environmental catastrophes, trade disruptions like the Ever Given obstruction of the Suez Canal, and geopolitical tensions have caused multiple disruptions to the life sciences supply chains. Recently, the war in Ukraine has caused new massive disruptions in all life sciences sectors, including the food sector. As one of Europe’s largest grain suppliers, the entire Ukraine grain production and trafficking has been heavily impacted. Sanctions and increasingly high tensions have caused further delays and disruptions.

Due to broken or bent supply chains, industry leaders are now looking at how to adapt to this new reality and discover what it means for their business. A new model is needed to accommodate inevitable disruptions. At the same time advancement in medical, pharmaceutical developments and the technological field, have made supply chain and logistics more intricate than ever. In this article, I explore the disruptions and issues facing supply chains, the effects on the life sciences industry, how companies can adapt to the challenges facing the industry, and how Amoria Bond can help companies attract professionals with the right skills.

The impact of covid-19 on the life sciences supply chains.

The Covid-19 pandemic caused major disruptions to life sciences supply chains in a very short period of time. Effects were felt immediately after countries all across the world implemented strict lockdowns to combat the spread of the virus. For example, many hospitals struggled to receive supplies of Personnel Protective Equipment (PPE), due to the large demand caused by the pandemic. Meanwhile, hospitals in many countries were operating at maximum capacity and required the equipment to safely interact with covid patients. Unfortunately, the supply chains were unable to keep up with demand and not enough protective equipment could be delivered, causing shortages in some hospitals. Hospital staff in a New York City hospital went so far as to create makeshift protective clothing out of garbage bags to have some form of protection while treating patients - a last resort that provided insufficient protection.

Furthermore, certain consumer goods like toilet paper and pasta were in short supply, as consumers started panic buying. The supply chains were unable to keep up with the increased demand due to people being confined to their homes, while businesses and restaurants were closed and demand for the same commodities in those sectors dropped significantly.

At the same time, manufacturers had to adapt their working process to lockdown rules and regulations within the countries they were operating. They had to deal with social-distancing protocols, employee quarantines, working from home, and an increase in sick leave - often resulting in a decrease in production.

For example, one of Europe’s largest meat producers and exporters, Vion, had to cope with multiple lockdowns due to large scale covid outbreaks in their facilities in The Netherlands, rising absenteeism from quarantined and unwell staff, and social distancing restrictions on the facility floors. The virus was able to spread especially fast in those locations due to cold temperatures and limited air circulation. As a result, they started testing employees every day when entering the facility, requiring a huge steady supply of testing material and an increase in costs. Vion reported a net loss of €29 million in 2021 stating the volatile market conditions, supply chain disruptions, and higher costs as reasons for the loss.

Companies soon discovered there was another different impact as a result of the supply chain disruptions caused by the pandemic: a large number of customer orders went unfulfilled as companies struggled to maintain the supply of their goods. These customer complaints resulted in lasting damage to brand reputation, which in turn resulted in increased reputation costs. For healthcare and pharmaceutical firms especially, damage to the firm’s image and customer complaints have been a major consequence of supply-chain disruptions over the past three years. The Economist Intelligence Unit (EIU) undertook a survey of senior supply-chain and procurement executives from the US and Europe. Their research found that disruptions have incurred substantial financial costs (from 6-10% of the annual revenues) and reputational costs in the form of customer complaints and brand reputation damage, and increased costs of operations.

Companies tried to adjust to the changes brought by the pandemic, and many managed to adapt. Suppliers adjusted their operations, companies found alternative suppliers, and supply and demand found a new equilibrium. In early 2022 the global pandemic is slowly coming to an end as many countries are completely lifting restrictions. This doesn’t mean that all issues facing supply chains are gone. Disruptions are increasingly common and most businesses face the challenge to adapt to these continuing changes. Most companies expect that disruptions will only increase in the coming decade. Trade disputes, cyberattacks, price fluctuations, geopolitical tensions like the Ukraine war, and an increase of natural disasters will impact supply chains far beyond the Covid-19 pandemic.

Thriving during the pandemic.

The covid-19 pandemic didn’t only cause disruptions in supply chains, it also provided an opportunity for certain pharmaceutical companies to adapt and thrive. Never before had the world seen how fast supply chains could adapt and change, as during the covid vaccine development and roll-out.

It was unprecedented how incredibly fast the development and roll-out of the covid-19 vaccines happened. Large Pharmaceutical companies managed to produce and test vaccines in record time, utilising new mRNA technologies. Not just that, they also managed to produce these vaccines on an incredibly large scale and distribute them all over the world. Just Pfizer alone produced over 3 billion doses of their mRNA vaccine in 2021 and is planning to produce over 4 billion doses in 2022.

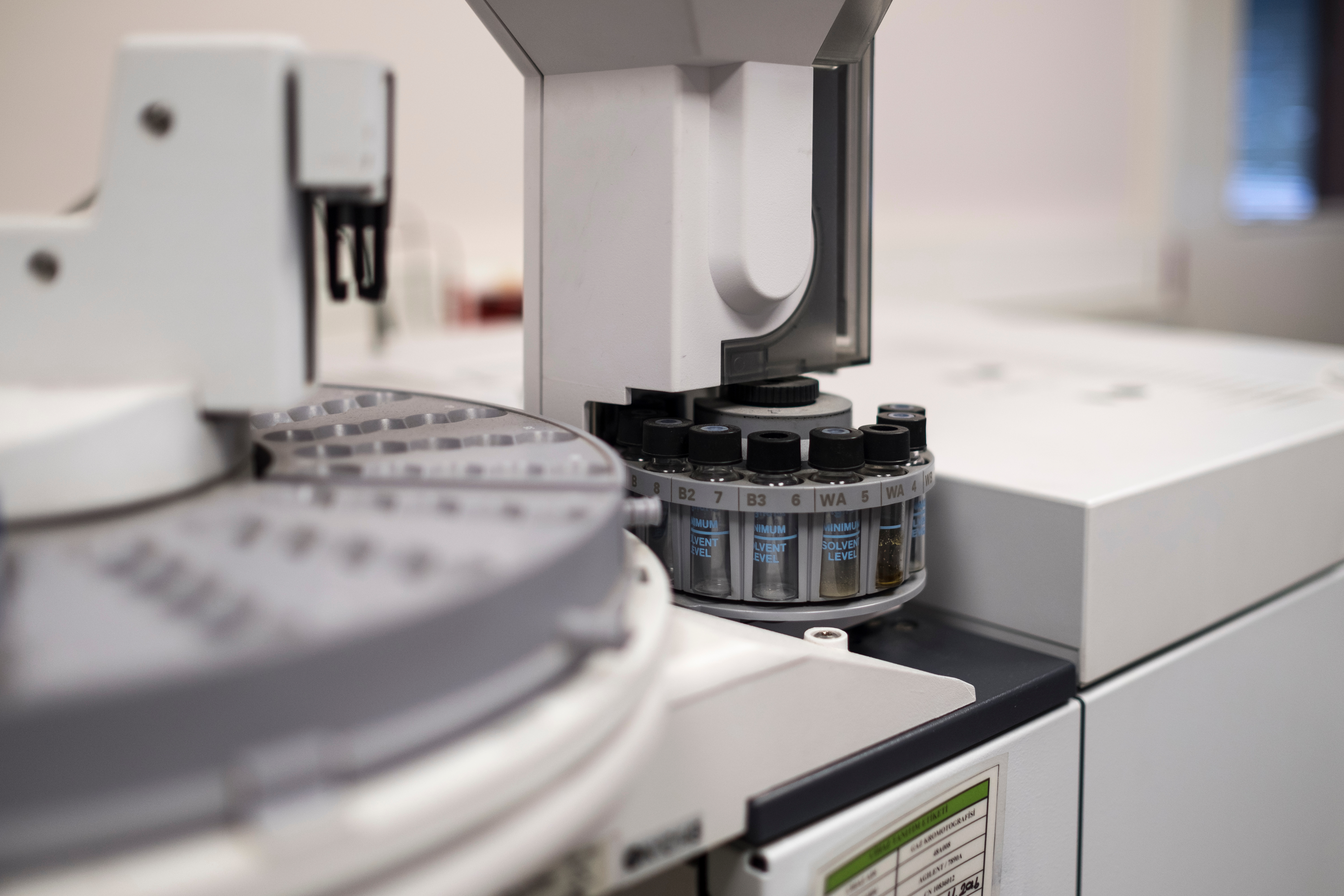

After solving the production puzzle, all of these vaccines needed to be distributed to almost every country in the world. To make matters more complicated, Pfizer’s vaccine needed to be kept between -90° and -60° celsius during shipping. To solve this issue Pfizer manufactured a specialized thermal shipper, nicknamed a “cool box”, for transporting the vaccine. These thermal shippers are about the size of a carry-on suitcase and are filled with dry ice made from carbon dioxide. They are equipped with a device that has a continuous GPS and temperature monitor. This advanced coolbox allowed the safe distribution of the vaccine to every corner of the globe. It’s a great example of how Pfizer utilized advanced technology to enable a streamlined distribution of their vaccine.

The development, distribution and rollout of the covid vaccines highlights the extreme capabilities that supply chains have to adapt and thrive in difficult situations. Furthermore, it shows a huge potential for the pharmaceutical industry to streamline medication production. Could a structure like this be adapted to medication for heart failure, dementia, or even cancer? Large pharmaceutical companies are now asking themselves the question, what can we learn from the covid-19 pandemic vaccine roll-out and apply to our other processes and supply chains?

Sourcing the right professionals

The market is moving fast and companies need to adapt to the speed of the market. We see a tendency for companies to continue business as usual, missing important opportunities to adapt to new technologies and move with the market. Agile and resilient supply chains are essential for organizations that want to stay ahead. Companies can’t afford to continuously let disruptions impact their business. A reinvention with a focus on agility and resilience is necessary.

To move forward, companies have to attract professionals that are capable of adapting supply chains and implementing new technologies into their supply chains. Companies that are succeeding in attracting new talent are moving fast. They are closing gaps and cutting down on processes. If you want to learn more about new technologies that impact supply chains read more in this article I wrote here.

What Amoria Bond does to help, is adopt new practices to speed up the hiring process of highly skilled industry professionals. We’ve developed specific methods and tools that streamlined the hiring process and we move fast. For example, we incorporate video interviews in a more engaging and revealing way, allowing companies to immediately get a good feeling about candidates without meeting them, making the next step easier and faster. Even if you don’t have time to interview candidates immediately, Amoria Bond can do the video interviews for you and show the company the completed videos, saving you time.

We’re able to fill roles in continuous improvement, demand planning, forecasting, OPEX/CAPEX and other supply chain process improvements for worldwide customers. Our teams have outstanding industry knowledge and will work with you to find the best person to fulfil your next supply chain and logistics position.

Amoria Bond wants to progress people's careers everywhere through our multi-award-winning recruitment company recognised by Global Recruiter, R.E.C and Talent Partners for providing the Best Client Services. We're proud of our reputation and track record for delivering quality, relevant professionals. We work quickly to get you the right people when you need them. Find out more about our recruitment and staffing services and how we can help hire your next supply chain and logistics specialist today.

Contact me or my team to discuss how we can help you.